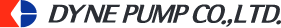

Loss of Water in The Pipe

(per 100M length [M])

Total Head Calculation Method

- H = h + hf

- hf = λ – 1/d – v/2g

- v = Q/A

- · H – Total head (M)

- · h – Actual head (position head) (M)

- · λ – Coefficient of friction of the pipe

- · g – Gravitational acceleration 9.8 (m/s2)

- · Q – Pumping quantity(m3/sec)

- · v – Flow velocity in pipe(m/sec)

- · d – Inner diameter of the tube (M)

- · A – Aperture cross-sectional area (m2)

Calculation of Required Power

· Pump water power (KW) = 0.163 x Total head (m) x Water volume

(m3/min) x Liquid specific gravity

· 3-phase rated output (KW)

= √3 x Rated voltage (V) x Rated current (A) x Motor efficiency x Motor power factor / 1000

· Pump shaft power (KW) = Water power / Pump efficiency

· Electric motor required power

= Pump shaft power x (1 + Extra power)

= (Motor extra power is about 10% = 0.1)

Calculation of Discharge Diameter According

to Pumping Quantity

| Caliber (mm) |

Flux (m3 / min) |

|---|---|

| 32 | 0.06 ~ 0.12 |

| 40 | 0.10 ~ 0.20 |

| 50 | 0.16 ~ 0.32 |

| 80 | 0.40 ~ 0.80 |

| 100 | 0.63 ~ 1.25 |

| 150 | 1.60 ~ 3.15 |

How to Start The Submersible Motor Pump

(We Recommend)

· Since the motor in the starting state is the same as the voltage device with the secondary side shorted, a large starting current

(400 ~ 600%) flows when the rated voltage is applied to the primary side, and there is a risk of damage to the original line, so use the following starting method.

· Line Start : 15KW or less

· Star-Delta Start : 18.5KW or more and 75KW or less

· Reactor Start : 90KW or more

· Compensator Start : 90KW or more

Motor Rotation Speed (By Number of Poles)

| number of pole | 60Hz | 50Hz | ||

|---|---|---|---|---|

| Synchronous speed | Pump speed | Synchronous speed | Pump speed | |

| 2 | 3600 | 3450 | 3000 | 2850 |

| 4 | 1800 | 1750 | 1500 | 1450 |

| 6 | 1200 | 1165 | 1000 | 950 |

| 8 | 900 | 875 | 750 | 720 |

| 10 | 720 | 700 | 600 | 580 |

| 12 | 600 | 585 | 500 | 485 |

| 14 | 514 | 500 | 429 | 410 |

| 16 | 450 | 435 | 375 | 365 |

| 18 | 400 | 390 | 333 | 325 |

| 20 | 360 | 350 | 300 | 290 |

Basic Unit Comparison Table

| 1 Mpa | 10.1972 kgf/cm2 |

|---|---|

| 1 kgf/cm2 | 0.0980665 Mpa |

| 1 psi | 0.070307 kgf/cm2 |

| 1 kgf/cm2 | 14322334 psi |

| 1 kg | 2.2046226 lb |

| 1 lb | 0.45359237 kg |

| 1 kgf | 9.80665 N |

| 1 N | 0.1019716 kgf |

| 1 M | 3.280840 Ft |

| 1 Ft | 0.304850 M |

| 1 m3/min | 264.1833 USGL/min |

| 1 USGL/min | 0.0037824 m3/min |

Resistance Loss of Various Piping Parts

(indicated by the equivalent length of a horizontal straight pipe [M])

| Part | Tube Inner Diameter | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | |

| 90˚Elbow | 0.90 | 0.20 | 1.50 | 2.10 | 2.40 | 3.00 | 4.20 | 5.10 | 6.00 |

| 45˚Elbow | 0.54 | 0.72 | 0.90 | 1.20 | 1.50 | 1.80 | 2.40 | 3.00 | 3.60 |

| 90˚T tube | 0.27 | 0.36 | 0.45 | 6.00 | 0.75 | 0.90 | 1.20 | 1.50 | 1.80 |

| Gate Valve | 0.18 | 0.24 | 0.30 | 0.39 | 0.48 | 0.63 | 0.81 | 0.99 | 1.20 |

| Globe Valve | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 24.0 | 37.5 | 42.0 | 49.5 |

| 90˚Elbow | ||

|---|---|---|

| Tube Inner Diameter | ||

| 25 | 32 | 40 |

| 0.90 | 0.20 | 1.50 |

| 50 | 65 | 80 |

| 2.10 | 2.40 | 3.00 |

| 100 | 125 | 150 |

| 4.20 | 5.10 | 6.00 |

| 45˚Elbow | ||

| Tube Inner Diameter | ||

| 25 | 32 | 40 |

| 0.54 | 0.72 | 0.90 |

| 50 | 65 | 80 |

| 1.20 | 1.50 | 1.80 |

| 100 | 125 | 150 |

| 2.40 | 3.00 | 3.60 |

| 90˚T tube | ||

| Tube Inner Diameter | ||

| 25 | 32 | 40 |

| 0.27 | 0.36 | 0.45 |

| 50 | 65 | 80 |

| 6.00 | 0.75 | 0.90 |

| 100 | 125 | 150 |

| 1.20 | 1.50 | 1.80 |

| Gate Valve | ||

| Tube Inner Diameter | ||

| 25 | 32 | 40 |

| 0.18 | 0.24 | 0.30 |

| 50 | 65 | 80 |

| 0.39 | 0.48 | 0.63 |

| 100 | 125 | 150 |

| 0.81 | 0.99 | 1.20 |

| Globe Valve | ||

| Tube Inner Diameter | ||

| 25 | 32 | 40 |

| 7.5 | 10.5 | 13.5 |

| 50 | 65 | 80 |

| 16.5 | 19.5 | 24.0 |

| 100 | 125 | 150 |

| 37.5 | 42.0 | 49.5 |

Friction Coefficient Table (For Steel Pipes and New Pipes) TORISIMA Coefficient

| Nominal Diameter |

Coefficient of Friction |

Nominal Diameter |

Coefficient of Friction |

Nominal Diameter |

Coefficient of Friction |

Nominal Diameter |

Coefficient of Friction |

|---|---|---|---|---|---|---|---|

| 40 | 0.0325 | 125 | 0.0240 | 250 | 0.0220 | 450 | 0.0211 |

| 50 | 0.0300 | 150 | 0.0233 | 300 | 0.0217 | 500 | 0.0210 |

| 80 | 0.0267 | 178 | 0.0228 | 350 | 0.0214 | 600 | 0.0208 |

| 100 | 0.0250 | 200 | 0.0225 | 400 | 0.0213 | 700 | 0.0207 |

| Nominal Diameter |

Coefficient of Friction |

Nominal Diameter |

Coefficient of Friction |

|---|---|---|---|

| 40 | 0.0325 | 50 | 0.0300 |

| 80 | 0.0267 | 100 | 0.0250 |

| 125 | 0.0240 | 150 | 0.0233 |

| 178 | 0.0228 | 200 | 0.0225 |

| 250 | 0.0220 | 300 | 0.0217 |

| 350 | 0.0214 | 400 | 0.0213 |

| 450 | 0.0211 | 500 | 0.0210 |

| 600 | 0.0208 | 700 | 0.0207 |

Water Drainage Submersible Motor Pump Efficiency (KS B 3621)

| Flow (m3/min) | 0.10 | 0.15 | 0.20 | 0.30 | 0.40 | 0.50 | 0.60 | 0.80 | 1.00 | 1.50 | 2.00 | 3.00 | 4.00 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A Efficiency (%) | 30.0 | 35.5 | 38.5 | 43.0 | 46.0 | 47.5 | 49.0 | 51.0 | 53.0 | 55.5 | 55.5 | 59.0 | 60.0 |

| B Efficiency (%) | 24.5 | 29.0 | 31.5 | 35.5 | 37.0 | 39.0 | 40.0 | 42.0 | 43.5 | 45.5 | 46.5 | 48.5 | 49.0 |

| Flow (m3/min) | A Efficiency (%) | B Efficiency (%) |

|---|---|---|

| 0.10 | 30.0 | 24.5 |

| 0.15 | 35.5 | 29.0 |

| 0.20 | 38.5 | 31.5 |

| 0.30 | 43.0 | 35.5 |

| 0.40 | 46.0 | 37.0 |

| 0.50 | 47.5 | 39.0 |

| 0.60 | 49.0 | 40.0 |

| 0.80 | 51.0 | 42.0 |

| 1.00 | 53.0 | 43.5 |

| 1.50 | 55.5 | 45.5 |

| 2.00 | 55.5 | 46.5 |

| 3.00 | 59.0 | 48.5 |

| 4.00 | 60.0 | 49.0 |

Submersible Pump Efficiency for Construction

| Flow (m3/min) | 0.1 | 0.2 | 0.4 | 0.6 | 0.8 | 1.0 | 1.5 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 8.0 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A Efficiency (%) | 29.0 | 35.0 | 42.0 | 44.0 | 46.0 | 47.0 | 48.0 | 49.0 | 50.0 | 50.5 | 51.0 | 51.5 | 52.0 |

| B Efficiency (%) | 22.0 | 28.0 | 33.6 | 35.2 | 37.0 | 37.6 | 38.4 | 39.2 | 40.0 | 40.5 | 41.0 | 41.5 | 42.0 |

| Flow (m3/min) | A Efficiency (%) | B Efficiency (%) |

|---|---|---|

| 0.1 | 29.0 | 22.0 |

| 0.2 | 35.0 | 28.0 |

| 0.4 | 42.0 | 33.6 |

| 0.6 | 44.0 | 35.2 |

| 0.8 | 46.0 | 37.0 |

| 1.0 | 47.0 | 37.6 |

| 1.5 | 48.0 | 38.4 |

| 2.0 | 49.0 | 39.2 |

| 3.0 | 50.0 | 40.0 |

| 4.0 | 50.5 | 40.5 |

| 5.0 | 51.0 | 41.0 |

| 6.0 | 51.5 | 41.5 |

| 8.0 | 52.0 | 42.0 |

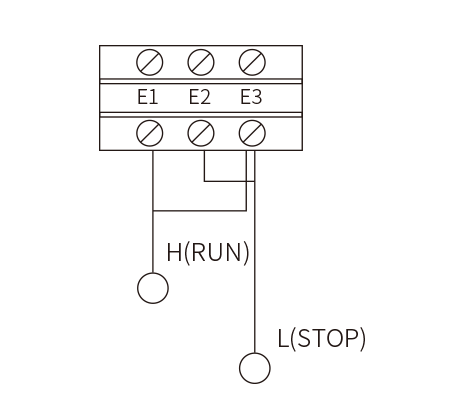

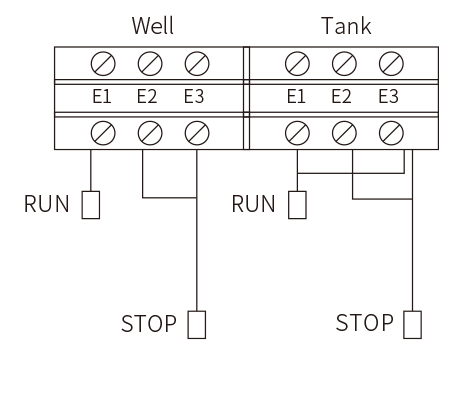

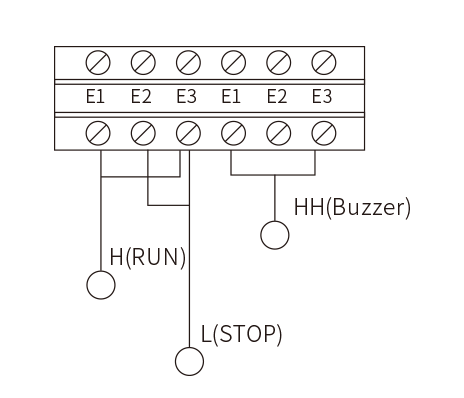

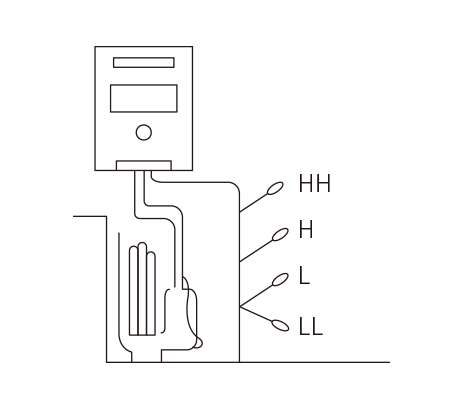

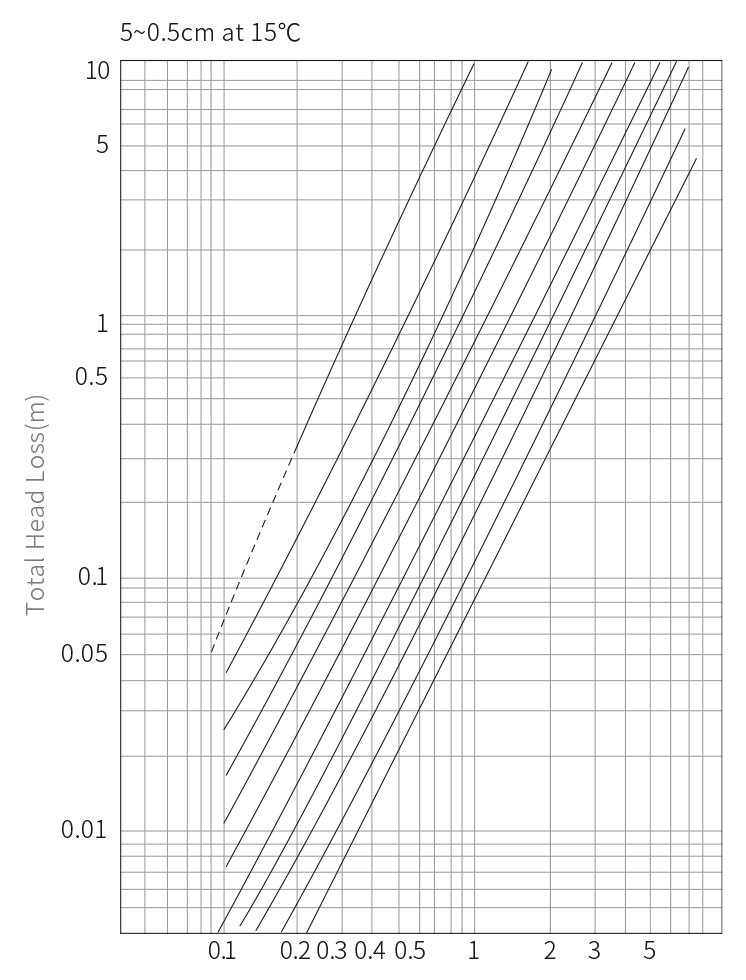

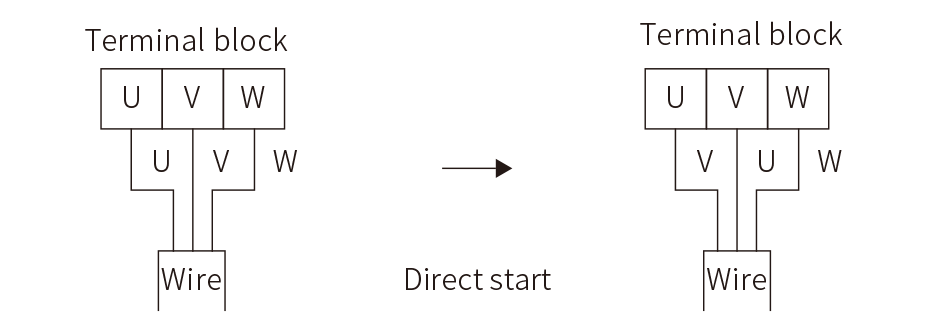

Motor Pump Terminal Block Connection Method (in reverse phase operation)

How to connect the level switch terminal block