DPS-260

DPS-450

DPS-750

DPS-750

DPS-1550

DPS-H1550

DPS-H1550

Standard Specification

* OPTION Selection : F → FLOAT SWITCH / L → LEVEL SWITCH

| Model | Phase / Number of Poles | Output (kw) |

Total Head (m) |

Maximum Pumping Quantity (l/min) |

Pumping Quantity / Head (l/min) |

Discharge Diameter (mm) |

|---|---|---|---|---|---|---|

| DPS-260 | 220V-1Φ-2P | 0.25 | 11 | 150 | 80 (7M) | 32 |

| DPS-450 | 220V-1Φ-2P | 0.4 | 13 | 280 | 150 (8M) | 50 |

| DPS-750 | 220V-1Φ-2P | 0.75 | 17 | 330 | 200 (10M) | 50 |

| DPS-1550 | 220V-1Φ-2P | 1.5 | 23 | 450 | 300 (15M) | 50 |

| DPS-H1550 | 220V-1Φ-2P | 1.5 | 32 | 300 | 150 (20M) | 50 |

| DPS-260 | |

|---|---|

| Phase / Number of Poles | 220V-1Φ-2P |

| Output (kw) |

0.25 |

| Total Head (m) |

11 |

| Maximum Pumping Quantity (l/min) |

150 |

| Pumping Quantity / Head (l/min) |

80 (7M) |

| Discharge Diameter (mm) |

32 |

| DPS-450 | |

| Phase / Number of Poles | 220V-1Φ-2P |

| Output (kw) |

0.4 |

| Total Head (m) |

13 |

| Maximum Pumping Quantity (l/min) |

280 |

| Pumping Quantity / Head (l/min) |

150 (8M) |

| Discharge Diameter (mm) |

50 |

| DPS-750 | |

| Phase / Number of Poles | 220V-1Φ-2P |

| Output (kw) |

0.75 |

| Total Head (m) |

17 |

| Maximum Pumping Quantity (l/min) |

330 |

| Pumping Quantity / Head (l/min) |

200 (10M) |

| Discharge Diameter (mm) |

50 |

| DPS-1550 | |

| Phase / Number of Poles | 220V-1Φ-2P |

| Output (kw) |

1.5 |

| Total Head (m) |

23 |

| Maximum Pumping Quantity (l/min) |

450 |

| Pumping Quantity / Head (l/min) |

300 (15M) |

| Discharge Diameter (mm) |

50 |

| DPS-H1550 | |

| Phase / Number of Poles | 220V-1Φ-2P |

| Output (kw) |

1.5 |

| Total Head (m) |

32 |

| Maximum Pumping Quantity (l/min) |

300 |

| Pumping Quantity / Head (l/min) |

150 (20M) |

| Discharge Diameter (mm) |

50 |

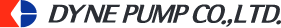

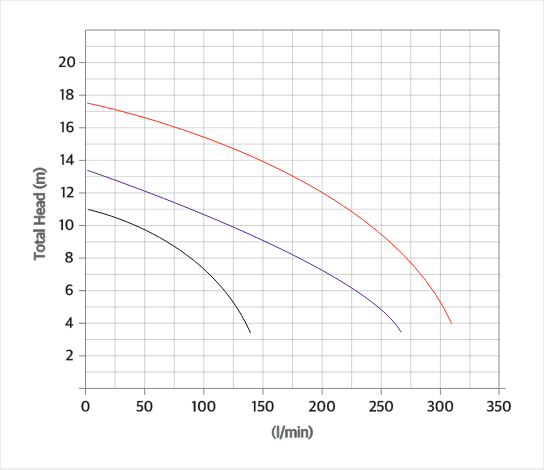

Performance Curve

* Caution : Dig a puddle and use the pump in it so that Performance Curve the motor part of the pump is not exposed to the water surface.

-

DPS-260

-

DPS-450

-

DPS-750

-

DPS-1550

-

DPS-H1550

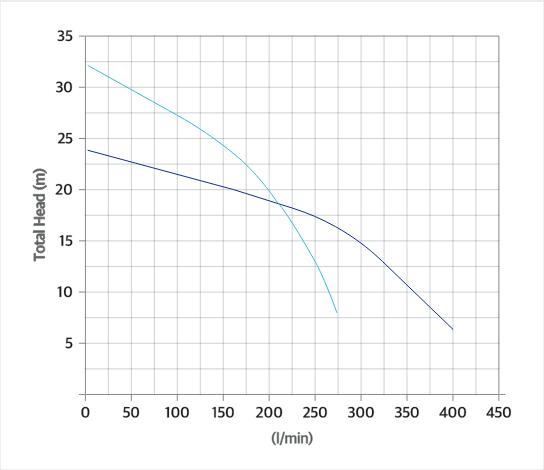

Appearance and Dimensions

| Exit (Ø) |

Model | Output (kw) |

Pump and Motor (mm) | Weight (kg) |

|||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | ||||

| 32 | DPS-260 | 0.25 | 183 | 93 | 124 | 73 | 120 | 322 | 7.35 |

| 50 | DPS-450 | 0.4 | 250 | 125 | 175 | 95 | 165 | 470 | 19 |

| DPS-750 | 0.75 | 250 | 125 | 175 | 95 | 165 | 470 | 19.5 | |

| DPS-1550 | 1.5 | 250 | 125 | 175 | 95 | 165 | 485 | 23 | |

| DPS-H1550 | 1.5 | 250 | 125 | 175 | 95 | 165 | 490 | 23 | |

* The above specifications are subject to change without notice.

* Exit (Ø) : 32

| DPS-260 | |||||

|---|---|---|---|---|---|

| Output (kw) | Weight(kg) | ||||

| 0.25 | 7.35 | ||||

| Pump and Motor (mm) | |||||

| A | B | C | |||

| 183 | 94 | 124 | |||

| D | E | F | |||

| 73 | 120 | 322 | |||

* Exit (Ø) : 50

| DPS-460 | |||||

|---|---|---|---|---|---|

| Output (kw) | Weight(kg) | ||||

| 0.4 | 18.5 | ||||

| Pump and Motor (mm) | |||||

| A | B | C | |||

| 255 | 140 | 180 | |||

| D | E | F | |||

| 105 | 180 | 425 | |||

| DPS-760 | |||||

| Output (kw) | Weight(kg) | ||||

| 0.75 | 20.7 | ||||

| Pump and Motor (mm) | |||||

| A | B | C | |||

| 255 | 140 | 180 | |||

| D | E | F | |||

| 105 | 180 | 460 | |||

| DPS-7603 | |||||

| Output (kw) | Weight(kg) | ||||

| 0.75 | 20.7 | ||||

| Pump and Motor (mm) | |||||

| A | B | C | |||

| 255 | 140 | 180 | |||

| D | E | F | |||

| 105 | 180 | 460 | |||

* The above specifications are subject to change without notice.

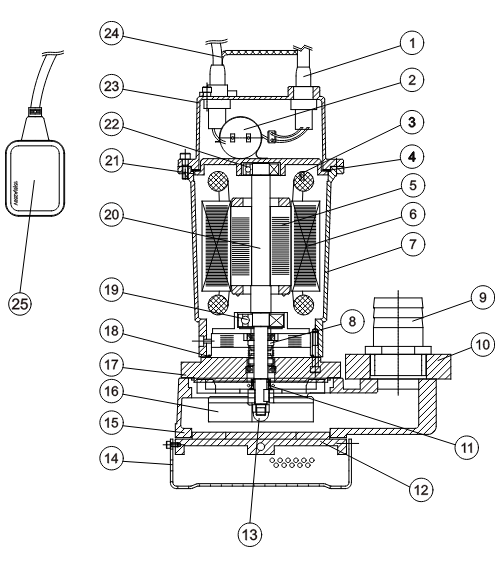

Assembly Drawing and Parts

| NO. | Description | NO. | Description |

|---|---|---|---|

| 1 | POWER CABLE | 14 | STRAINER |

| 2 | CAPACITOR | 15 | CASING |

| 3 | BIMETAL | 16 | IMPELLER |

| 4 | HEAD PACKING | 17 | OIL CHABER BRACKET |

| 5 | ROTOR | 18 | O RING |

| 6 | STATOR | 19 | BEARING |

| 7 | FRAME | 20 | SHAFT |

| 8 | MECHANICAL SEAL | 21 | END BRACKET (TOP) |

| 9 | ADAPTER | 22 | BEARING |

| 10 | FLANGE | 23 | HEAD COVER |

| 11 | SHAFT RING | 24 | HANDLE |

| 12 | SUCTION COVER | 25 | FLOAT S/W |

| 13 | CAP NUT |

Usage

Underground parking lot drainage / Fountain

Fountain

Drainage and water supply of garden water / Agricultural water / Industrial water

Drainage of underground leachate

Elevator PIT drainage

Drainage of miscellaneous water at construction / Civil engineering works

Features and Materials

Corrosion Prevention

Standard application of corrosion-resistant STS bolts

Adopted SHAFT STS304, which is resistant to corrosion

Triple Leakage Prevention Structure

Adopts double mechanical seal

PH / Handling Solution Temperature

PH 6~8 / 5~40 ℃

Water Leakage Protection Standard

IP68