Standard Specification

| Model | Phase / Number of Poles | Output (kw) |

Total Head (m) |

Maximum Pumping Quantity (㎥/min) |

Pumping Quantity / Head (㎥/min) |

Weight (kg) |

Discharge Diameter (mm) |

|---|---|---|---|---|---|---|---|

| DTB08-2 | 380V-3Φ-2P | 0.75 | 13 | 0.36 | 0.16 (10M) | 25 | 50 |

| DTB15-2 | 380V-3Φ-2P | 1.5 | 22 | 0.55 | 0.25 (15M) | 32 | 50 |

| DTB22-3 | 380V-3Φ-2P | 2.2 | 25 | 0.7 | 0.3 (20M) | 44 | 80 |

| DTB37-3 | 380V-3Φ-2P | 3.7 | 27 | 1 | 0.5 (20M) | 58 | 80 |

| DTB55-3 | 380V-3Φ-2P | 5.5 | 33 | 1.3 | 0.6 (25M) | 67 | 80 |

| DTB75-4 | 380V-3Φ-2P | 7.5 | 39 | 1.6 | 0.8 (30M) | 83 | 100 |

| DTB08-2 | |

|---|---|

| Phase / Number of Poles | 380V-3Φ-2P |

| Output (kw) |

0.75 |

| Total Head (m) |

13 |

| Maximum Pumping Quantity (㎥/min) |

0.36 |

| Pumping Quantity / Head (㎥/min) |

0.16 (10M) |

| Weight (kg) |

25 |

| Discharge Diameter (mm) |

50 |

| DTB15-2 | |

| Phase / Number of Poles | 380V-3Φ-2P |

| Output (kw) |

1.5 |

| Total Head (m) |

22 |

| Maximum Pumping Quantity (㎥/min) |

0.55 |

| Pumping Quantity / Head (㎥/min) |

0.25 (15M) |

| Weight (kg) |

32 |

| Discharge Diameter (mm) |

50 |

| DTB22-3 | |

| Phase / Number of Poles | 380V-3Φ-2P |

| Output (kw) |

2.2 |

| Total Head (m) |

25 |

| Maximum Pumping Quantity (㎥/min) |

0.7 |

| Pumping Quantity / Head (㎥/min) |

0.3 (20M) |

| Weight (kg) |

44 |

| Discharge Diameter (mm) |

80 |

| DTB37-3 | |

| Phase / Number of Poles | 380V-3Φ-2P |

| Output (kw) |

3.7 |

| Total Head (m) |

27 |

| Maximum Pumping Quantity (㎥/min) |

1 |

| Pumping Quantity / Head (㎥/min) |

0.5 (20M) |

| Weight (kg) |

58 |

| Discharge Diameter (mm) |

80 |

| DTB55-3 | |

| Phase / Number of Poles | 380V-3Φ-2P |

| Output (kw) |

5.5 |

| Total Head (m) |

33 |

| Maximum Pumping Quantity (㎥/min) |

1.3 |

| Pumping Quantity / Head (㎥/min) |

0.6 (25M) |

| Weight (kg) |

67 |

| Discharge Diameter (mm) |

80 |

| DTB75-4 | |

| Phase / Number of Poles | 380V-3Φ-2P |

| Output (kw) |

7.5 |

| Total Head (m) |

39 |

| Maximum Pumping Quantity (㎥/min) |

1.6 |

| Pumping Quantity / Head (㎥/min) |

0.8 (30M) |

| Weight (kg) |

83 |

| Discharge Diameter (mm) |

100 |

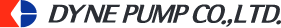

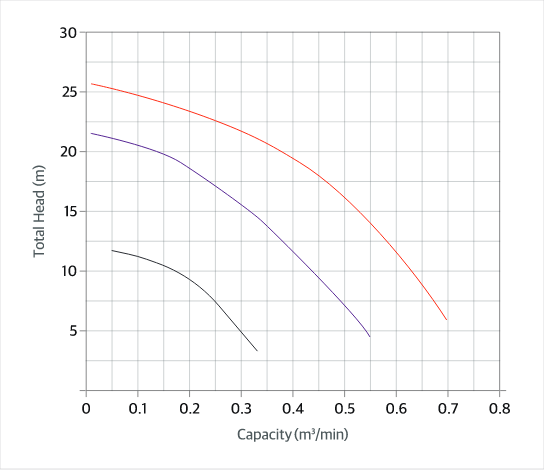

Performance Curve

* Caution : Dig a puddle and use the pump in it so that the motor part of the pump is not exposed to the water surface.

-

DTB08-2

-

DTB15-2

-

DTB22-3

-

DTB37-3

-

DTB55-3

-

DTB75-4

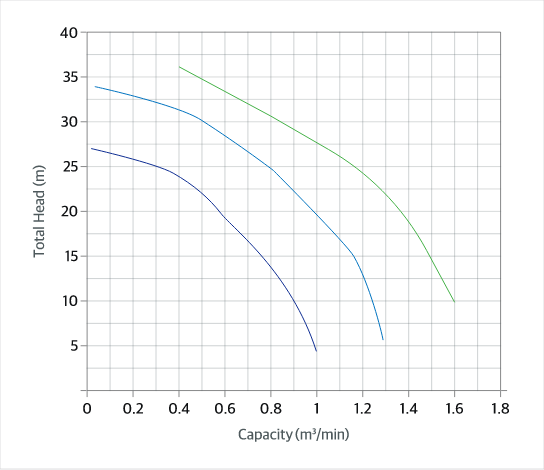

Appearance and Dimensions

| Exit (Ø) |

Model | Output (kw) |

Pump and Motor (mm) | Weight (kg) |

|||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | ||||

| 50 | DTB08-2 | 0.75 | 400 | 210 | 215 | 485 | 215 | 175 | 50 | 300 | 25 |

| DTB15-2 | 1.5 | 410 | 215 | 240 | 550 | 240 | 200 | 50 | 350 | 32 | |

| 80 | DTB22-3 | 2.2 | 480 | 255 | 250 | 550 | 250 | 205 | 80 | 430 | 44 |

| DTB37-3 | 3.7 | 520 | 290 | 290 | 670 | 290 | 255 | 80 | 500 | 58 | |

| DTB55-3 | 5.5 | 520 | 290 | 290 | 700 | 290 | 250 | 80 | 500 | 67 | |

| 100 | DTB75-4 | 7.5 | 580 | 320 | 310 | 720 | 310 | 280 | 100 | 500 | 83 |

* The above specifications are subject to change without notice.

* Exit (Ø) : 50

| DTB08-2 | |||

|---|---|---|---|

| Output (kw) | Weight(kg) | ||

| 0.75 | 25 | ||

| Pump and Motor (mm) | |||

| A | B | C | D |

| 400 | 210 | 215 | 485 |

| E | F | G | H |

| 215 | 175 | 50 | 300 |

| DTB15-2 | |||

| Output (kw) | Weight(kg) | ||

| 1.5 | 32 | ||

| Pump and Motor (mm) | |||

| A | B | C | D |

| 410 | 215 | 240 | 550 |

| E | F | G | H |

| 240 | 200 | 50 | 350 |

* Exit (Ø) : 80

| DTB22-3 | |||

|---|---|---|---|

| Output (kw) | Weight(kg) | ||

| 2.2 | 44 | ||

| Pump and Motor (mm) | |||

| A | B | C | D |

| 480 | 255 | 250 | 550 |

| E | F | G | H |

| 250 | 205 | 80 | 430 |

| DTB37-3 | |||

| Output (kw) | Weight(kg) | ||

| 3.7 | 58 | ||

| Pump and Motor (mm) | |||

| A | B | C | D |

| 520 | 290 | 290 | 670 |

| E | F | G | H |

| 290 | 255 | 80 | 500 |

| DTB55-3 | |||

| Output (kw) | Weight(kg) | ||

| 5.5 | 67 | ||

| Pump and Motor (mm) | |||

| A | B | C | D |

| 520 | 290 | 290 | 700 |

| E | F | G | H |

| 290 | 250 | 80 | 500 |

* Exit (Ø) : 100

| DTB75-4 | |||

|---|---|---|---|

| Output (kw) | Weight(kg) | ||

| 7.5 | 83 | ||

| Pump and Motor (mm) | |||

| A | B | C | D |

| 580 | 320 | 310 | 720 |

| E | F | G | H |

| 310 | 280 | 100 | 500 |

* The above specifications are subject to change without notice.

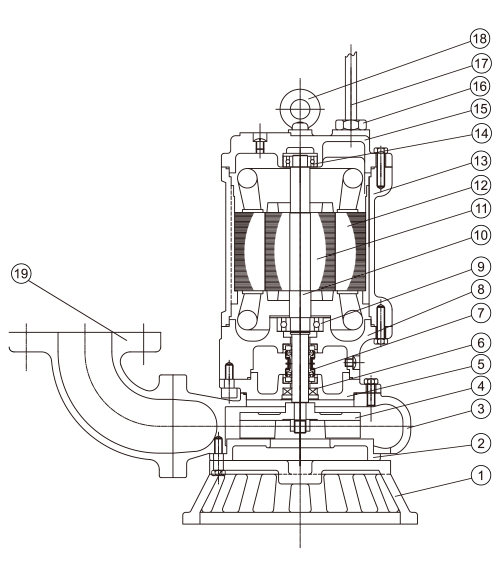

Assembly Drawing and Parts

| NO. | Name of Parts | Material |

|---|---|---|

| 1 | STAND | GC200 |

| 2 | SUCTION COVER | GC200 |

| 3 | CASING | GC200 |

| 4 | IMPELLER | GC200 |

| 5 | SEAL CHAMBER | GC200 |

| 6 | OIL SEAL | NBR |

| 7 | MECHANICAL SEAL | SIC |

| 8 | BEARING HOUSING | GC200 |

| 9 | LOWER BEARING | |

| 10 | MOTOR SHAFT | STS304 |

| 11 | ROTOR | |

| 12 | STATOR | |

| 13 | MOTOR FRAME | GC200 |

| 14 | UPPER BEARING | |

| 15 | BRACKET | GC200 |

| 16 | CABLE CAP | BC6 |

| 17 | POWER CABLE | |

| 18 | EYE BOLT | STS304 |

| 19 | ELBOW | GC200 |

Usage

For sewage and drainage of factories and large buildings

For sewage and drainage of underground shopping malls, apartment complexes, and subways

For sewage and drainage of other high lifts

For pumping water from the merged treatment plant

For draining fountains and decorative waterfalls

Features and Materials

Pump Impeller

SEMI-OPEN IMPELLER

Economic

Economical power consumption by improving pump efficiency

Highest Performance

Best performance in high lift

Perfect Waterproof Function

Perfect waterproof function using Double Mechanical Seal

Automatic Detachment

Quick and simple installation using automatic detachment device